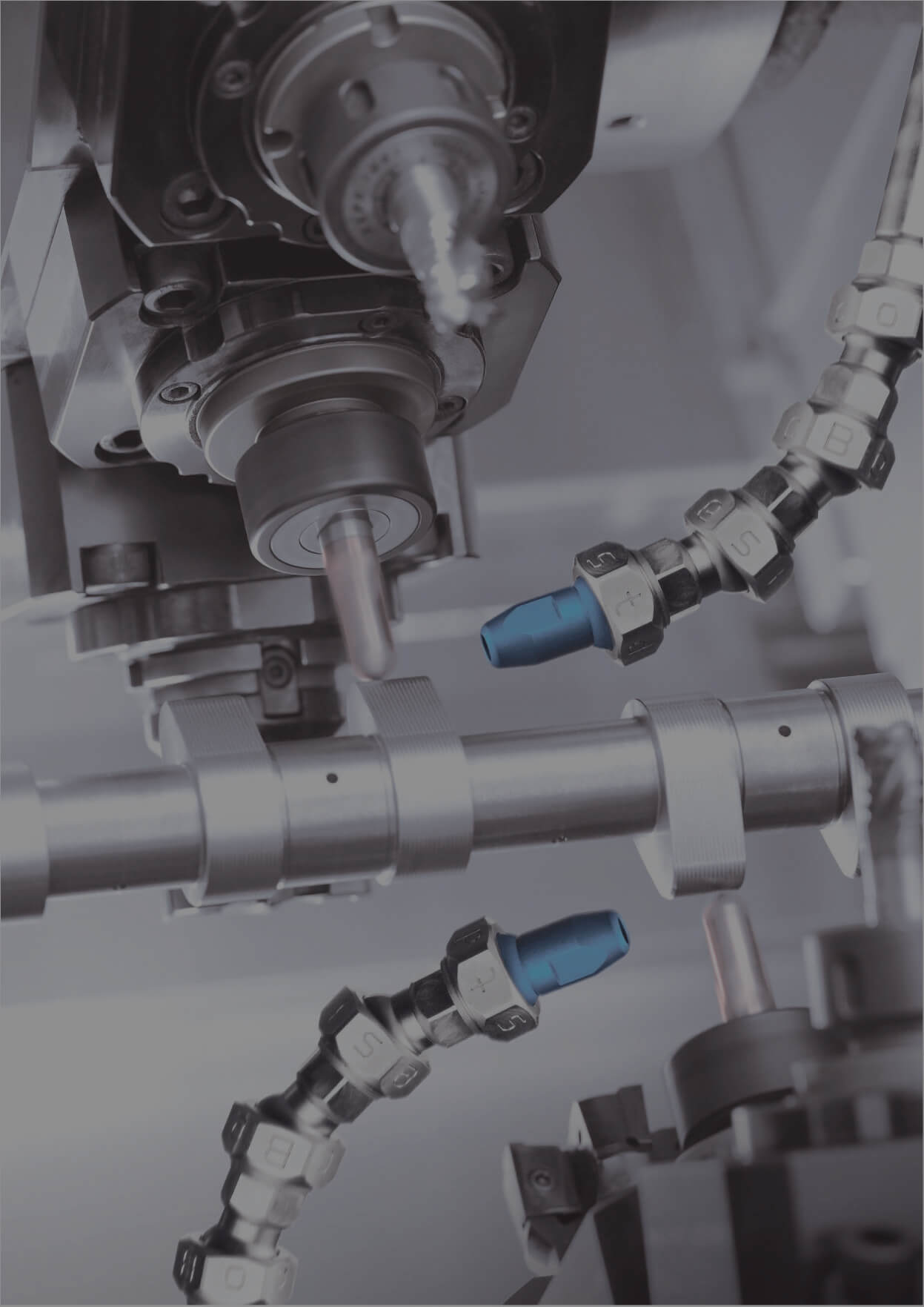

Longer tool lifespans and less machine downtime for lathes and milling machines

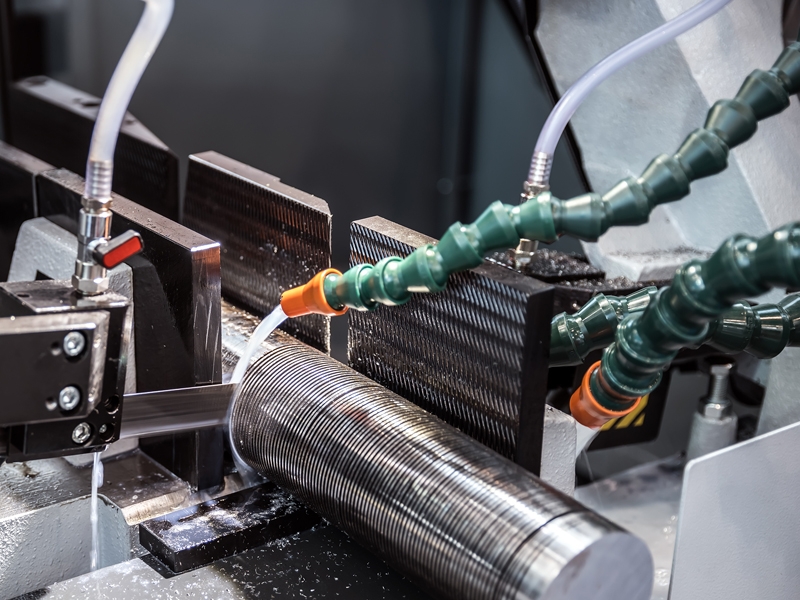

The problem with plastic hoses:

- Elevated coolant pressures cannot be achieved

- The position can be adjusted by vibration and chips

- The cooling is not reliable and targeted

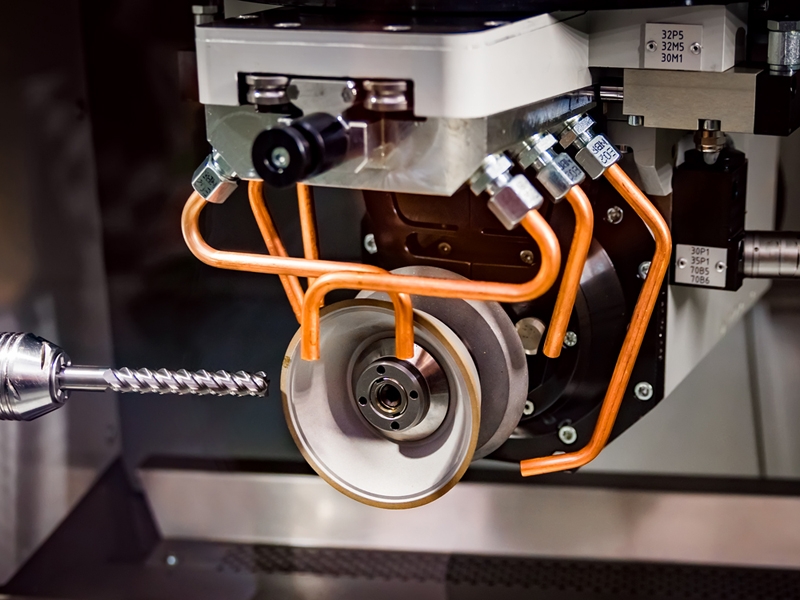

The problem with curved copper or steel pipes:

- Long rust/setup/bending times

- No nozzle technology

- Cannot be reproduced

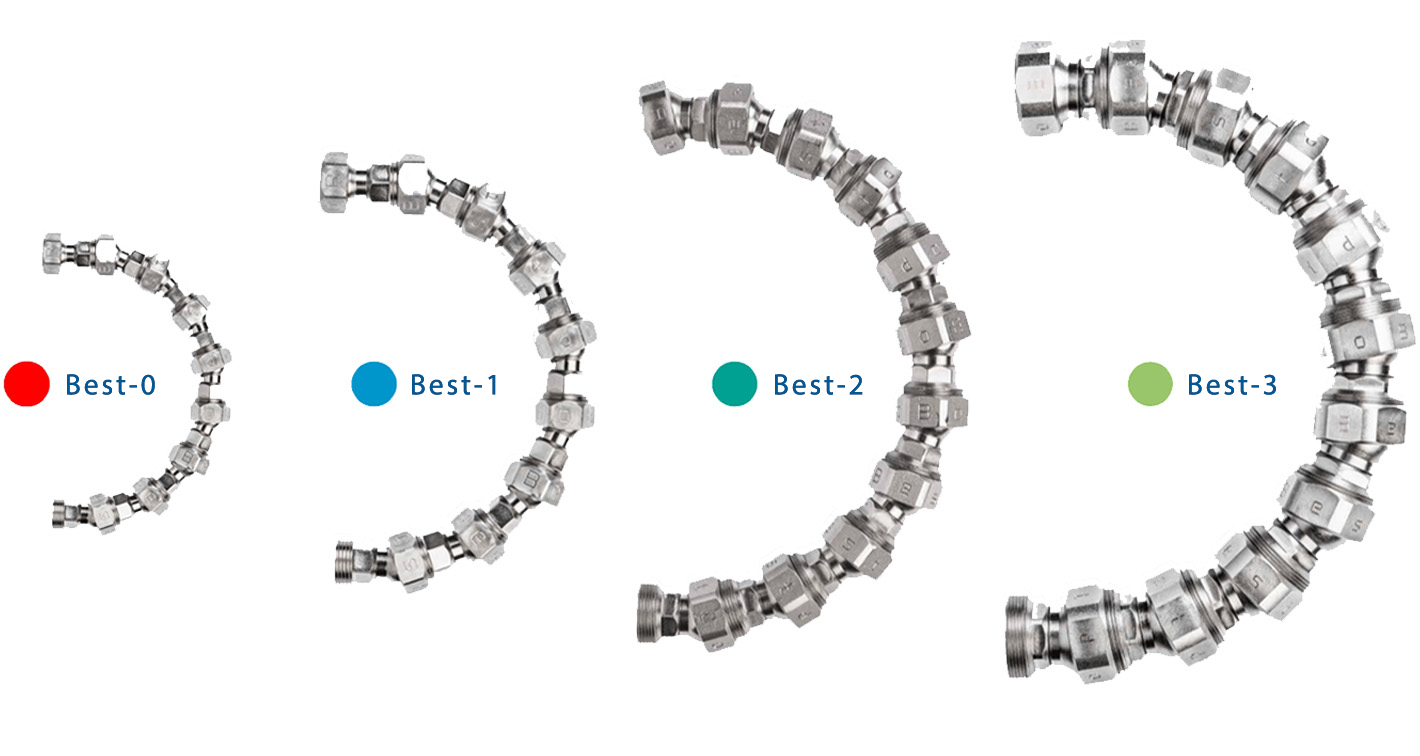

Advantages of BESTDO

- Easy to assemble

- Can be adjusted with pinpoint accuracy

- Precise alignment even if there are high levels of vibration and significant chip formation

- Can be individually configured (modular system)

- Flexible yet rigid (can be screwed in)

- Pressure-resistant up to 50 bar

- Low levels of wear (long service life)

- Increase in process reliability

- Increase in tool stand time

- Latest nozzle technology

- Rapid changing system

- Can also be used with compressed air

Erhalten Sie die neusten Informationen und Branchentrends direkt per E-Mail!

Jetzt zum Newsletter anmelden.